ECOLOFLEX SPC ®

The World`s First TBT-Free Hydrolyzing Self-Polishing Antifouling

ECOLOFLEX SPC - The first TBT-Free hydrolyzing self-polishing antifouling in the world from Nippon Paint, which contains a special acrylate copolymer developed with our patented technology as the basic resin, and cuprous oxide as the main biocide. The product has been applied to far over 10,000 ships (As of December 2005). In 2003, its perfect antifouling performance was proved on 4 large containers after the operation for 59 to 61 months. We are challenging constantly to improve the performance more and more.

How the ECOLOFLEX SPC can help protect your ship?

• Excellent antifouling

performance

By reconstruction of the resin synthesis and structure,

together with improved formulation technology, the

actions of polishing take place evenly and continuously

and the leaching of biocide gradually proceeds in

a controlled manner, thereby excellent anti-fouling

performance can be expected.

• Long-term ship`s operation

The leaching of biocide steadily and continuously

proceeds, as long as the paint film exists, by which

long-term operation will be ensured excellent anti-foulinq

performance of existing paint film thickness

• Excellent smoothing

and roughness control

The self polishing mechanism results in excellent

smoothing and roughness control, along with the

smoothness of the surface without the accumulation

of the skeleton layer.

• Protect the oceans from

polluting

TBT-Free "ECOLOFLEX SPC" will protect the oceans

from pollution. "ECOLOFLEX SPC" will coexist with

the environment of the earth.

ECOLOFLEX SPC anti-fouling performance

• Anti-fouling mechanism

of ECOLOFLEX SPC

By the chemical reaction (Hydrolysis) which occurs

when the paint film contacts seawater, the surface

layer of the paint film gradually leaches out in

a controlled manner and Copper Acrylate Copolymer

is released. As the fresh active paint surface is

always exposed as long as the ECOLOFLEX SPC paint

film exists, long-term anti-fouling performance

and service period can be ensured

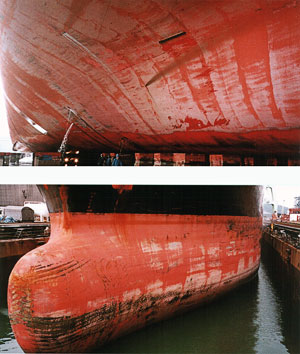

• Polishing mechanism

of ECOLOFLEX SPC

Polishing mechanism works by the leaching of biocide

with the chemical reaction (Hydrolysis) and the

physical motion of seawater. This motion of seawater

will reduce the surface roughness and the surface

friction resistance, resulting in excellent smoothing/roughness

control, which leads to reduced fuel consumption

and long-term service period. The polishing rate

differs with ships' operating condition, i.e., seawater

temperature, seawater pH, speed and trade route/history

etc

Anti-fouling mechanism of hydrophilic and self depletion type

This type of antifouling paint was developed for the tin-free requirement, and consists of special water soluble or water swell able resins. On contact with seawater, these special synthetic resins dissolve/swell/bond with water. The motion of seawater against the surface of paint film removes the loosely adhering dissolved/swelled/ bonded layer and releases the biocides from the paint film. But this cannot match the smoothing property and controlled biocide release of hydrolysis antifouling. Self depletion antifouling is also called hydrophilic antifouling and can be categorized as "self-polishing antifouling", but it is based on a technology which cannot avoid thick leached layer build-up (150~200tlm thick) after service.

• Leaching speed of anti-fouling

in dynamic/static condition

(A) Dynamic: (Dynamic + Static condition)

n cycle test

(B) Static :Static condition

ECOLOFLEX SPC

• Immediately after application

Self polishing mechanism results in excellent smoothing/roughness

control, along with complete fouling control.

• In-Service period

The leaching of biocide gradually proceeds in a

controlled manner, which leads to reduced fuel consumption

• Subsequent docking(s)

As the remaining paint film makes complete surface

by re-application, there are no need to carry out

over-all application of A/C

Comparison of Ecoloflex SPC with hydrophilic/self depletion type

| Surface Condition of Paint Film | Leaching of Biocide | Term of Antifouling Performance | Smoothing and Roughness Control | Overcoatability | |

| Hydrolysis | The fresh active paint surface is always exposed, as the motion of seawater polishes away the leached layer with no skeleton layer. | As long as the paint film exists, long-term stable release of biocide is maintained. | Anti-fouling life is proportional to the film thickness and long term service period is expected. | Surface roughness is reduced by the motion of seawater and the surface becomes smooth . | As anti-fouling property of the remaining paint film is maintained enough, only the polished amount of Ecoloflex SPC needs to be applied. A certain minimum amount of film thickness is remained. |

| Hydrophilic /Self Depletion | The paint surface swells and the swelled layer is physically removed from the surface by the motion of seawater and the actions of swelling and removal take place unevenly and discontinuously with no smooth paint surface. | The leached layer is physically removed with some reduction of surface roughness control and thick leached layer hinders anti-fouling property, as the biocides leach out earlier. | Anti-fouling life is not proportional to the film thickness and there are limits of ability. | Not smooth enough in-service period. | As the leached layer is thick and it's film strength declines, detachment may occur within the swelled/leached layer on repeated dockings. |

Selection of ECOLOFLEX SPC

• Selection of Ecoloflex SPC depends on:

- Expected Docking Interval

- Speed x In-service Days/year =

Travel Distance/year - Route (Seawater Temperature)

- Age of Vessel

In selection of Ecoloflex SPC System, designed to reduce the cost for operation and ensure regular service by smoothing the film surface, the travel distance/year can be an important factor. The higher polishing rate reduces the fuel cost but the film gets thicker and another cost will go up. Generally, the effect of cost reduction reveals soon after docking, so fast-polishing type can be applied as a top coat. NPMC offers a full line of Ecoloflex SPC series deciding the specifications taking above into consideration .

A/C system for ECOLOFLEX SPC

A/C system plays an important role to enhance the performance of Ecoloflex SPC. We recommend the tar-free NOA System characterized by Self Indicating (SI) technology, which enables a painter to visually judge if the correct film thickness has been achieved during the application process.

• Maintenance and Repair

NOA 10M

NOA 10M is A/C touch up one coat system for maintenance

and repair and can be applied to the whole outer

hull including boot top and topsides without separation

of painting area.

• Newbuilding

1. NOA 10F +NOA A/C II

NOA 1OF allows unlimited intervals for by-self and

for NOA A/C II overcoating and for various kinds

of finishes in above water areas.

2. UNIPRIME 100

Abrasion resistant universal primer

3. UNIPROTECTOR + NOA A/C II

Abrasion resistant long-life system