Work case study ›

Original condition of the ship`s hull. Surface is covered with heavy rust. Some minor welding job is necessary and blast cleaning is required

More information:

Surface Preparation![]() (PDF)

(PDF)

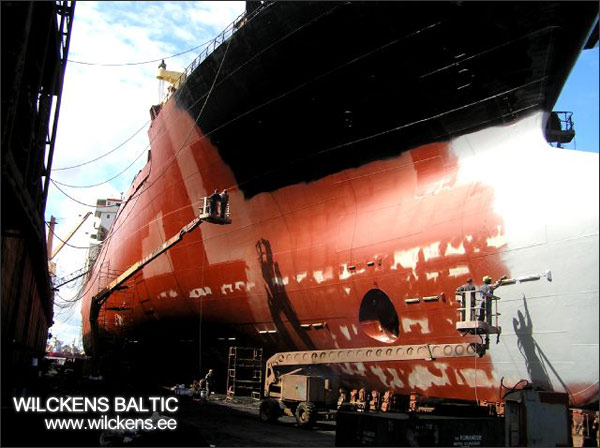

Surface after blast cleaning is covered with Wilckens anticorrosive EPOSIST 2000 CEP (ERCD) 3900 (red brown) coating on underwater and topside parts of the vessel

More information on this coat:

EPOSIST 2000 CEP 3900 ![]() (PDF)

(PDF)

Surface is covered with the second EPOSIST 2000 coat . Underwater part is being covered with EPOSIST 2000 CEP 7001(Grey). Topside is being covered with EPOSIST 2000 CEP 9005 (Black)

Already we can see attractive optical result but it still has a lot of work ahead

Third coat WILKOPOX VC EPPV 1501 (buff) is being applied to underwater part as intermediate coat for antifouling layer

More information on this coat:

WILKOPOX VC EPPV 1501![]() (PDF)

(PDF)

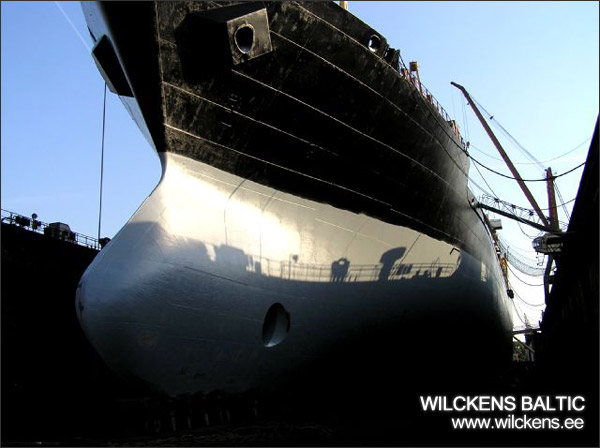

Underwater part is covered with the final antifouling layer. Surface is very glossy and optical results are excellent. Ship is ready and looks like new.

Only best results with Wilckens coatings